Product Description:

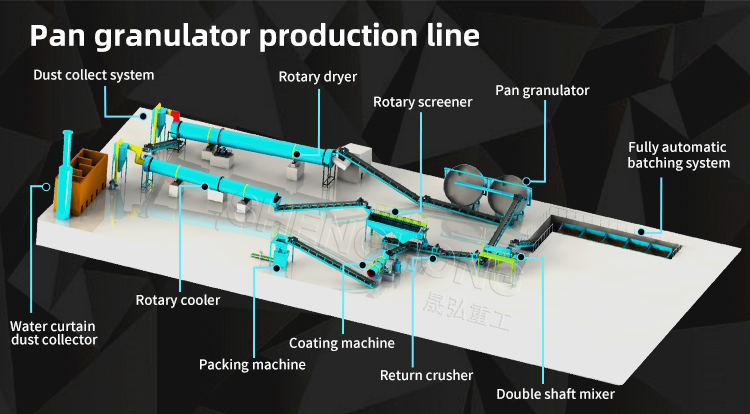

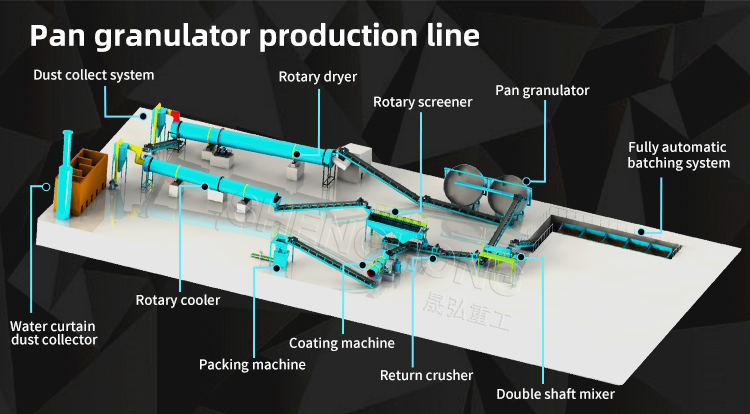

Disk granulator production line is a kind of production line

equipment widely used in fertilizer, chemical industry, metallurgy

and other industries. Its core equipment is a disk granulator,

which granulates materials through a rotating disk. The production

line also includes feeding system, drying system, screening system

and other links, forming a complete production line

Performance characteristics:

The production line of disc granulator has the advantages of simple

operation and convenient maintenance, which greatly reduces the

production cost and operation difficulty. First of all, it uses an

advanced control system, which can precisely control the parameters

of the granulation process, such as particle size, density, etc.,

to ensure stable and reliable product quality. Secondly, the

production line has the characteristics of high efficiency and high

yield, which can complete the pelleting task of a large number of

materials in a short time and improve production efficiency. In

addition, the disk granulator production line also has good

environmental performance, the use of closed operation, effectively

reduce dust pollution, in line with modern environmental

requirements.

Working principle:

In the production line of the disk granulator, the raw materials

are first pretreated by crushing, mixing, etc., and then enter the

disk granulator for granulation through the feeding system. The

granulated material enters the drying system for drying treatment

to remove excess water and improve the strength and stability of

the particles. Finally, the material is sifted through the

screening system to obtain the particle product that meets the

requirements. The disk granulator production line has the

advantages of high production efficiency, stable product quality

and low energy consumption. At the same time, the production line

is also equipped with an intelligent control system, which can

monitor the parameters in the production process in real time and

automatically adjust them to ensure the stable operation of the

production line.

Technical Parameters:

| del | Diameter of granulation disc(mm) | Edge height(mm) | Rotation speed(r/min) | Motor power(kw) | Capacity(t/h) | Lenght*width*height(mm) | | SHQ-80 | 800 | 200 | 25 | 1.5 | 0.1-0.2 | 900*1100*1000 | | SHQ-10 | 1000 | 250 | 21 | 2.2 | 0.3-0.5 | 1400*1200*1400 | | SHQ-15 | 1500 | 250 | 17 | 3 | 0.5-0.8 | 1750*1620*2000 | | SHQ-18 | 2000 | 300 | 17 | 5.5 | 0.6-1 | 2000*1980*2100 | | SHQ-20 | 2500 | 350 | 13.6 | 7.5 | 1-1.5 | 2200*2800*2700 | | SHQ-25 | 2500 | 350 | 13.6 | 7.5 | 1-1.5 | 2200*2800*2700 | | SHQ-28 | 2800 | 400 | 13.6 | 11 | 1.8-3 | 3100*2350*3060 | | SHQ-30 | 3000 | 450 | 11 | 11 | 3-4.5 | 3400*2500*3165 | | SHQ-32 | 3200 | 450 | 10 | 15 | 3.5-5 | 3500*2600*3350 | | SHQ-36 | 3600 | 450 | 10 | 22 | 5-7 | 4000*2990*3460 | | SHQ-45 | 4500 | 600 | 12 | 30 | 13-18 | 5030*3750*4300 |

|

|---|

Packing and Shipping:

Our organic fertilizer production line is carefully packaged to

ensure safe delivery to customers. The packaging materials are

environmentally friendly and recyclable.

Each component of the production line is wrapped with protective

material to prevent any damage during transportation. The packaging

is also clearly labeled to indicate the contents and operating

instructions.

We offer a variety of shipping options to meet our customers'

specific needs. Our lines can be shipped by sea, air, or land,

depending on the destination. We also offer expedited shipping for

rush orders.

For international orders, we handle all necessary customs and

documentation requirements to ensure a smooth delivery. Our team

works closely with reliable shipping companies to ensure timely and

efficient delivery of our products.

Upon receipt, we recommend inspecting the packaging and its

contents for any signs of damage. If any damage occurs, please

contact our Customer Service Team for assistance.

Thank you for choosing our organic fertilizer production line. We

strive to provide customers with the best quality products and

services.

Company introduction

Zhengzhou Shenghong Heavy Industry Technology Machinery Co.,

Ltd.(Short for "Shenghong Heavy Industry Technology") , was

established in 1999 as a professional fertilizer production

equipment manufacturer. Today, with over 20 years of experience,

Shenghong Heavy Industry is recognized as an expert in process

design and manufacturing on fertilizer industry. Shenghong Heavy

Industry consistently helps companies to turn ideas into realized

processes, solving material and process problems.

Customer visit

Installation site

FAQ:

Q1: What is the brand name of this fertilizer production line?

A1: The brand name of this fertilizer production line is Shenghong

Heavy Industry.

Q2: What is the model number of this fertilizer production line?

A2: The model number of this fertilizer production line is SH-.

Q3: Where is this fertilizer production line made?

A3: This fertilizer production line is made in Henan, China.

Q4: What certifications does this fertilizer production line have?

A4: This fertilizer production line is certified with ISO9001.

Q5: What is the minimum order quantity for this fertilizer

production line?

A5: The minimum order quantity for this fertilizer production line

is 1.

Q6: What is the price of this fertilizer production line?

A6: The price of this fertilizer production line is negotiable.

Q7: What are the packaging details for this fertilizer production

line?

A7: The packaging details for this fertilizer production line are

based on customer demand, usually in a container.

Q8: What is the delivery time for this fertilizer production line?

A8: The delivery time for this fertilizer production line is 15

days.

Q9: What are the payment terms for this fertilizer production line?

A9: The payment terms for this fertilizer production line are L/C

and T/T.

Q10: What is the supply ability for this fertilizer production

line?

A10: The supply ability for this fertilizer production line is 80

sets per month.