NPK Organic Fertilizer Granules Making Machine Production Line

Introduction of NPK Organic Fertilizer Granules Making Machine

Production Line

NPK Organic Fertilizer Production Line Plant is widely used in

producing chemical fertilizer, NPK fertilizer and the capacity

ranges from 5,000-200,000 tons/year. It is mainly used for

producing spherical particles with a diameter ranging from 1mm to

5mm.This equipment can specially used for processing compound

fertilizers with different concentrations and types, such as

organic fertilizer, inorganic fertilizer and biological fertilizer,

etc.

Advantages of NPK Organic Fertilizer Granules Making Machine

Production Line

1.Widely suitable for compound fertilizer, chemical, fodder and so

on.

2.Adopts advanced granulator, granulating ratio is up to 90%, with

high intensity.

3.The inner cylinder body adopts high quality rubber plate lining

structure which prevents the raw material from sticking on the

plate.

4.Stable performance, anti-corrosion, abrasion proof, low energy

consumption, long service lifespan, easy maintenance and

operation,etc.

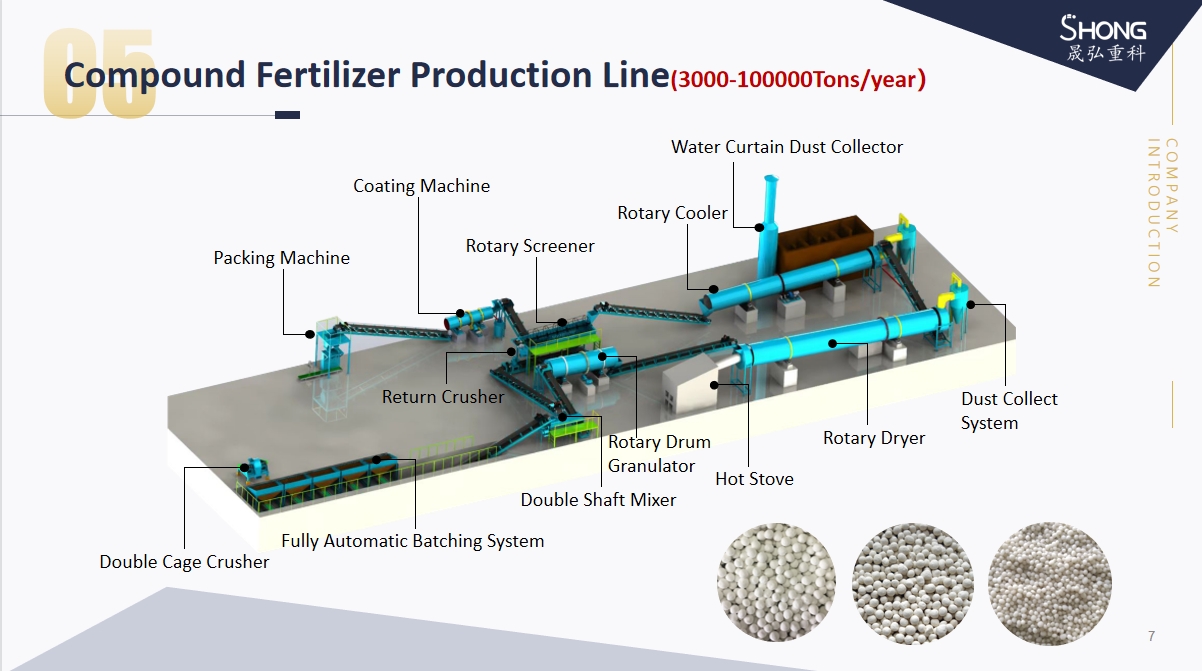

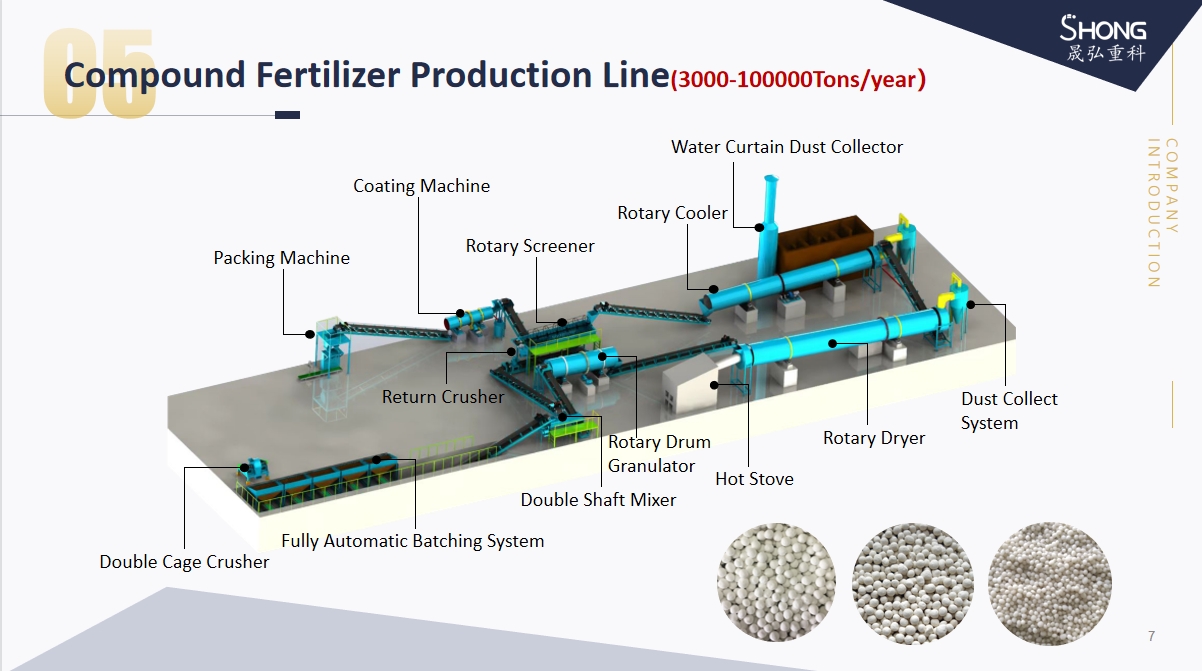

Working Process of NPK Organic Fertilizer Granules Making Machine

Production Line

Urea npk fertilizer production plant includes crusher, mixer,

granulator, dryer, cooler, screening machine, packing machine,belt

conveyor and other accessories,etc.

1.Vertical Chain Crusher

Put different raw materials into the vertical chain crusher. The

raw materials will be crushed into small particles, so that they

can meet the needs of the granulating process.

2.Disc Mixer

After crushing, they will be sent into the disc mixer, in which the

raw materials will be uniformly blended. The lining of the pan is

made of polypropylene or stainless steel sheet, which helps improve

the working efficiency as well as the production quality.

3.Granulator

The granulating process is the most important part of the whole

production line. Compound fertilizer production line mainly uses

double roller granulator and rotary drum granulator. You can tell

us your raw materials, our technicians will suggest you the best

granulator accordingly.

4.Rotary Drum Dryer

During the drying process, the water contents of granulated

particles will be dried, so that the particles will be harder and

easier to store. The whole body is sealed, in which the materials

will be contacted with the hot air with the continuous rotation of

the drum.

5.Rotary Drum Cooler

After the drying process, the temperature of the particles is a

little high, so they need to be cooled before the packing process.

The cooler adopts the most advanced cooling technology in the world

and makes the temperature of the particles is higher than the room

temperature for 3 to 5 degrees Celsius.

6.Rotary Drum Screening Machine

After entering the rotary drum screening machine, the qualified

particles will be sent into the coating machine, while the

unqualified particles will be selected and then sent into the

vertical chain crusher to be granulated again.

7.Rotary Fertilizer Coating Machine

The qualified particles will be coated by fertilizer coating

machine, which will beautify the particles and strengthen their

hardness at the same time. The fertilizer coating machine can

prevent the caking of the fertilizer particles effectively.

8.Fertilizer Packaging Machine

After the particles are coated, they will be packed by the packing

machine. The fertilizer packing machine is highly automatic, which

makes the packing process more efficient and accurate.