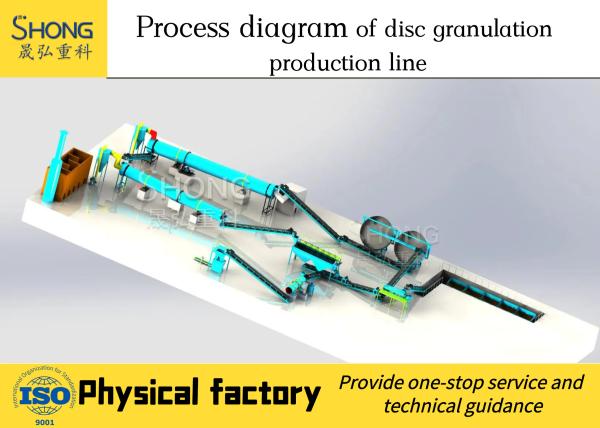

1-20t/H Capacity Organic Fertilizer Production Line

Technical Process for Granule Organic Fertilizer Plant

The entire production line is mainly used to process materials (cow

dung, sheep dung, pig dung, chicken dung, sludge, rice straw, corn

straw) and other animal manure organic waste after fermentation and

decomposing, which contains about 30%-35% moisture content. After

crushing and sieving, the binder (bentonite, humic acid) and other

ingredients that need to be proportioned are measured in the

batching mixing system according to the proportioning requirements.

(Adding functional bacteria can produce biological organic

fertilizer, adding nitrogen and phosphorus , Potassium (the total

nutrient content is less than 15%) can produce organic and

inorganic fertilizer) dosing, mixing, the fully mixed material is

uniformly and continuously fed into the granulator by the belt

conveyor, and then rounded into spherical particles by the

polishing and shaping machine. After drying at low temperature and

high air volume by dryer (≤65ºC), it is cooled and sieved. The

finished particles are conveyed to the finished product silo by

belt, and are measured and packed into storage by the computerized

quantitative packaging system.

1.Materials dewater

Liquid manure of animals content high moisture,which should be

dewater then enter to next process.

2.Fermentation

The crushed stalks and animal manure need to be fermentation to

kill a large number of animal fecal bacteria,parasite,etc.When the

materials is fermentation,it need turning,so fermentation can be

more thorough.

3.Materials crushing

The animal manure in blocks after fermentation,it should be crushed

through the pulverizer,which become relatively fine power is

suitable for granulation.

4.Mixing

The mixed material should be mixed completely,then get into

granulator.

5.Granulation

There are several types fertilizer granulator,if we produce organic

fertilizer,it is better to use disc fertilizer granulator.

6.Drying

After granulating,the moisture of fertilizer is bit high,it is not

suitable for long-term storage so we need send make drying process.

7.Cooling

The cooling machine is used to cool the hot fertilizer.

8.Screening

There are some non-uniform particles,after sieved screening

machine,the small particle diameter may be screened down for twice

processing.

9.Coating

Under the particle surface is not uniform,sleek case,we need to be

coat the surface of fertilizer granules.

10.Packaging

After package,the fertilizer can be sold.

Raw material of Granule Organic Fertilizer Plant

1. Agricultural waste: straw, dregs of beans, cotton dregs, rice

bran, etc.

2. Animal and Poultry manure: mixture of poultry litter and animal

waste, such as the wastes of slaughterhouse, fish market, urine and

dung of cattle,pigs, sheep, chicken, ducks, geese, goat, etc.

3. Industrial waste: wine lees, vinegar residue, manioc waste,

sugar scum, furfural residue, etc.

4. Home scrap: food waste, the roots and leaves of vegetables, etc.

5. Sludge: the sludge of the river, sewer, etc.

Raw materials

| Make organic fertilizer raw materials |

| Agricultural waste | Straw,dregs of beans,cotton dregs,rice bran,etc |

| Animal manure | Mixture of poultry litter(PL) and animal waste,slaughterhouse

waste,fish maket,urine and dung of

cattle,pigs,sheep,chicken,ducks,geese,goat,etc |

| |

| Home scrap | Food waste,bones,the roots and leaves of vegetables,etc |

| Mineral | Humic acid,bentonite,dolomite,etc |

| Others | Sludge of the rive,the sewer,etc |