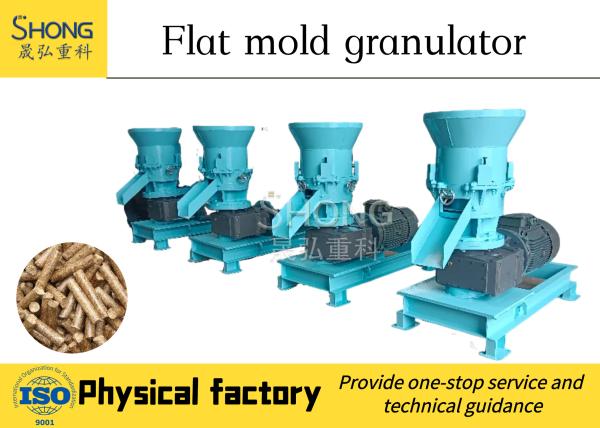

Cylinder Type Flat Die Press Granulator Organic Fertilizer

Production Line

Introduction of Fertilizer Production Line

Organic fertilizer production line is mainly used to produce

different organic fertilizers that are derived from animal waste, agricultural waste,industrial waste and kitchen waste,etc.It not only reduces environment pollution,but also makes

rational use of resources.

The Raw Material of Fertilizer Production Line

| No. | Category | Raw materials list |

| 1 | Agricultural waste | straw, dregs of beans, cotton dregs, rice bran, biogas waste,

mushroom waste, etc. |

| 2 | Animal waste | slaughterhouse waste, fish market waste, urine and dung of chicken,

pig, cattle, sheep ducks, geese, goat, etc. |

| 3 | Industrial waste | wine lees waste, vinegar waste, manioc waste, sugar waste, etc. |

| 4 | Home waste | food waste, bones, the roots and leaves of vegetables, etc. |

| 5 | Mineral | humic acid, bentonite, dolomite, etc. |

| 6 | Sludge | river sludge, pond sludge, sewage sludge, city sludge, etc. |

The Process of Fertilizer Production Line

Organic fertilizer production line usually includes 8 processes,

fermenting, grinding, mixing, granulating, drying, cooling,

screening and packaging. Fermenting, Crushing, mixing, granulating

and screening processes are necessary. Other processes are optional

based on different capacity.

Fermentation process

The fermentation of bio-organic raw materials plays quite a basic role in the whole production.Sufficient fermentation lays a solid

foundation for the quality of the end products. Groove type compost

turner can thoroughly compost and turn high-stacked fermentation materials

with large production capacity.Self-propelled compost turner can work freely outside or inside the factory,greatly increasing

the speed of aerobic fermentation.It is natural compost at the open place or in the compost tank with

ceil; normally the compost fertilizer need about 5-8 days to

ferment, and become purer organism.

The Benefits of Fertilizer Production Line

1. Low invest, good economic returns, high efficiency

2. Reasonable design, advanced technology, compact arrangement of

the whole production line.

3. Stable operation, energy saving, convenient to maintain.

4. Wide application for the raw materials. We can produce compound

fertilizer of various kinds with different density.